Industry Insight - Machining

Machining: The Foundation of Modern Manufacturing

Have you ever wondered how the countless metal products around us—from tiny screws to massive industrial equipment—are created? Behind this lies a precise technology: Machining.

What is Machining?

In simple terms, machining is the process of shaping a block of metal material into the desired shape and size using various tools and machines. Imagine you have a piece of clay that you can mold into different shapes; machining is like the metal version of molding clay, except we use much more precise tools and harder materials.

Diverse Machining Methods

There are many ways to perform machining, each with its unique advantages and applications. Here are several primary machining services our company provides:

(1) Milling

Milling is a versatile machining process suitable for cutting flat surfaces, slopes, grooves, or other geometric shapes. Milling machines use high-speed rotating cutters, typically made of high-speed steel or carbide, possessing extreme hardness and wear resistance. Milling is commonly used to manufacture complex parts requiring high precision, such as mechanical components.

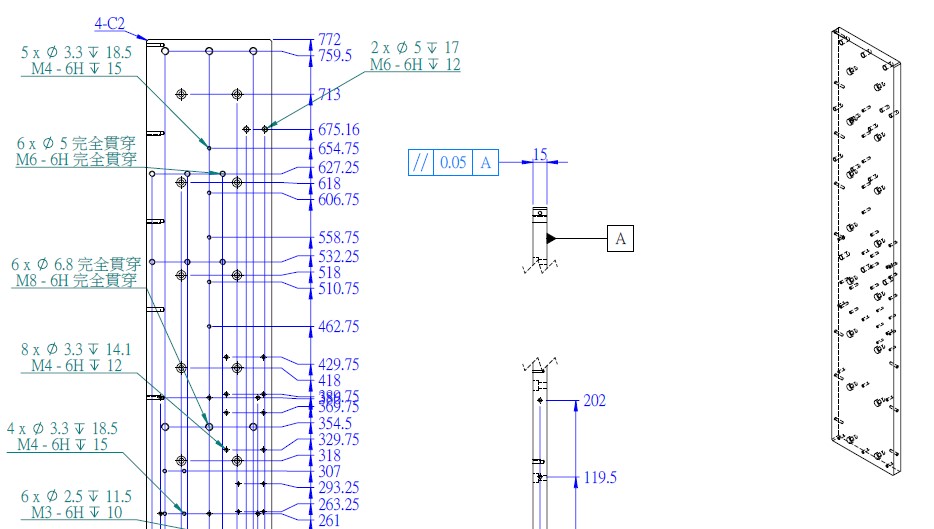

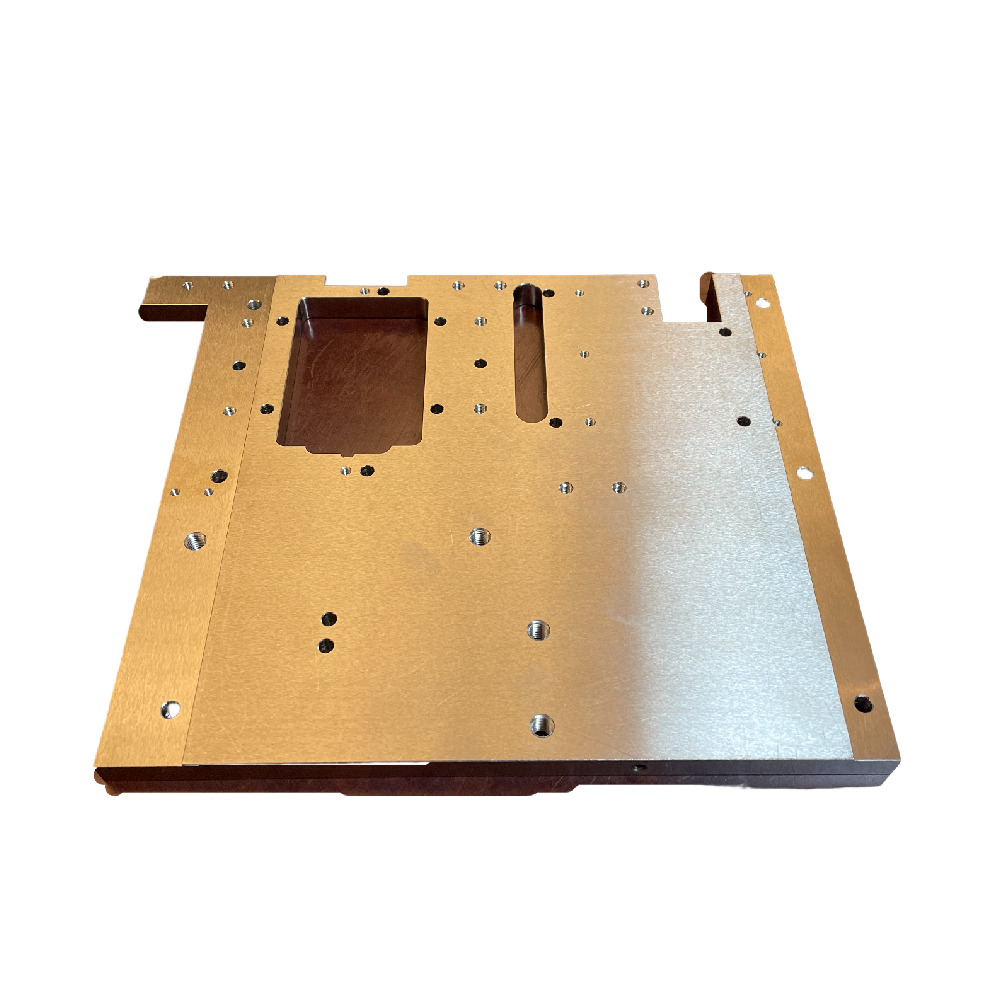

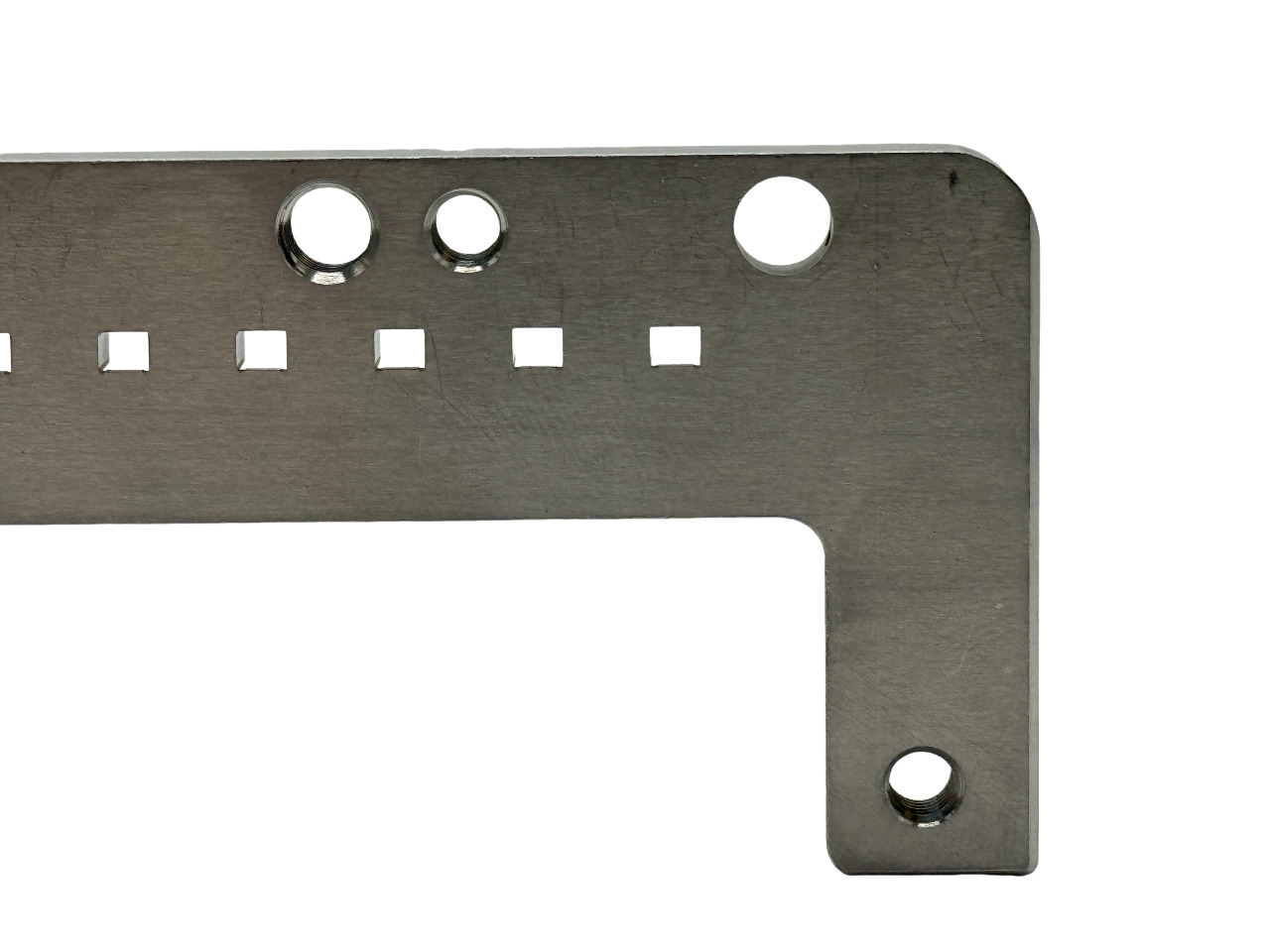

Case Study: We frequently machine mechanical components or fixtures for clients, transforming raw rectangular metal blocks into precise products through multiple cutting and flipping processes.

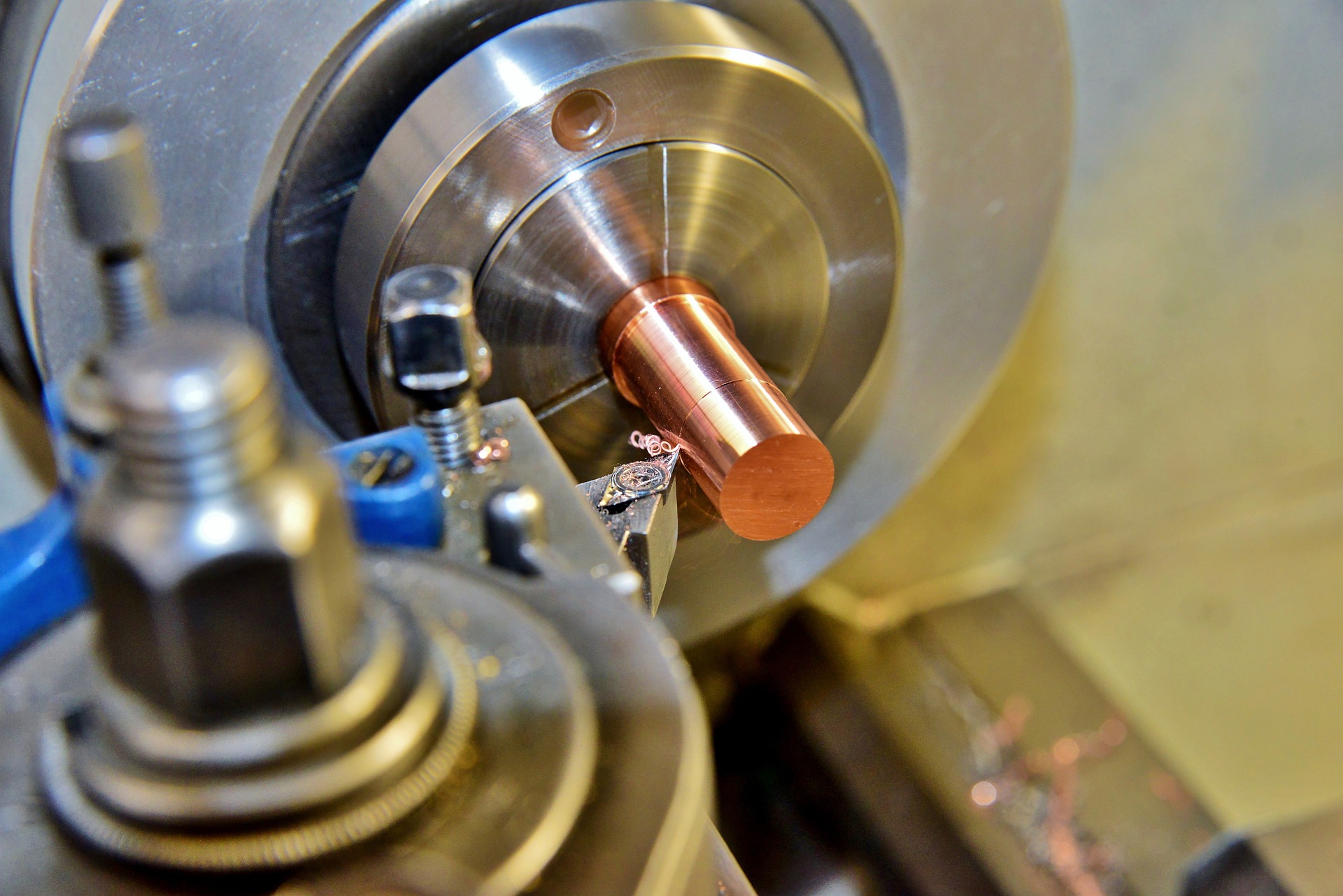

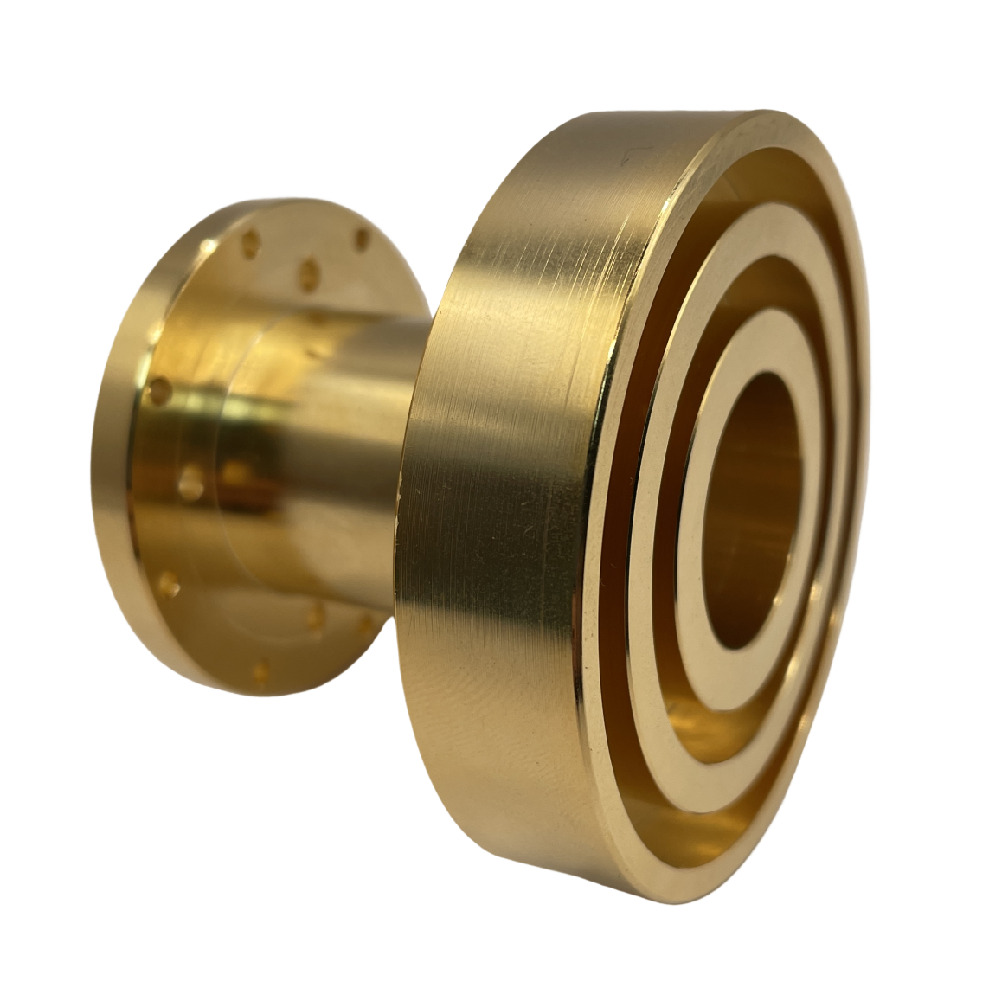

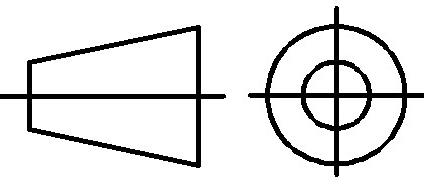

(2) Turning

Lathes are among the oldest and most commonly used machining equipment, primarily used for processing rotationally symmetrical workpieces. In the turning process, the workpiece is fixed on a rotating spindle, and the cutting tool moves linearly along the workpiece to remove material and form the desired shape. Common turning operations include outer diameter (OD), inner diameter (ID), facing, and threading. Turning is efficient and precise, suitable for manufacturing shaft and disk parts like bearings and screws.

Case Study: Our turning technology can precisely shape a standard cylindrical bar into various functional components.

(3) Grinding

Grinding is a precision machining process that uses an abrasive wheel as a cutting tool to remove material from the workpiece surface, achieving high precision and low surface roughness. This process is commonly used for parts requiring extreme flatness and fine finishes, such as bearings and mechanical seals.

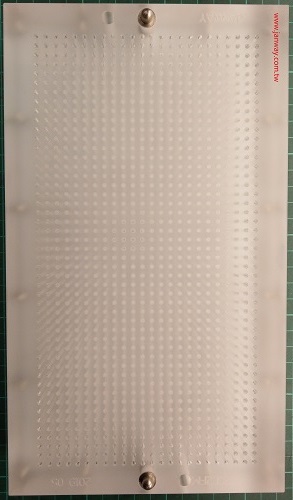

Case Study: CNC milled products processed by us achieve superior flatness and precision after undergoing grinding.

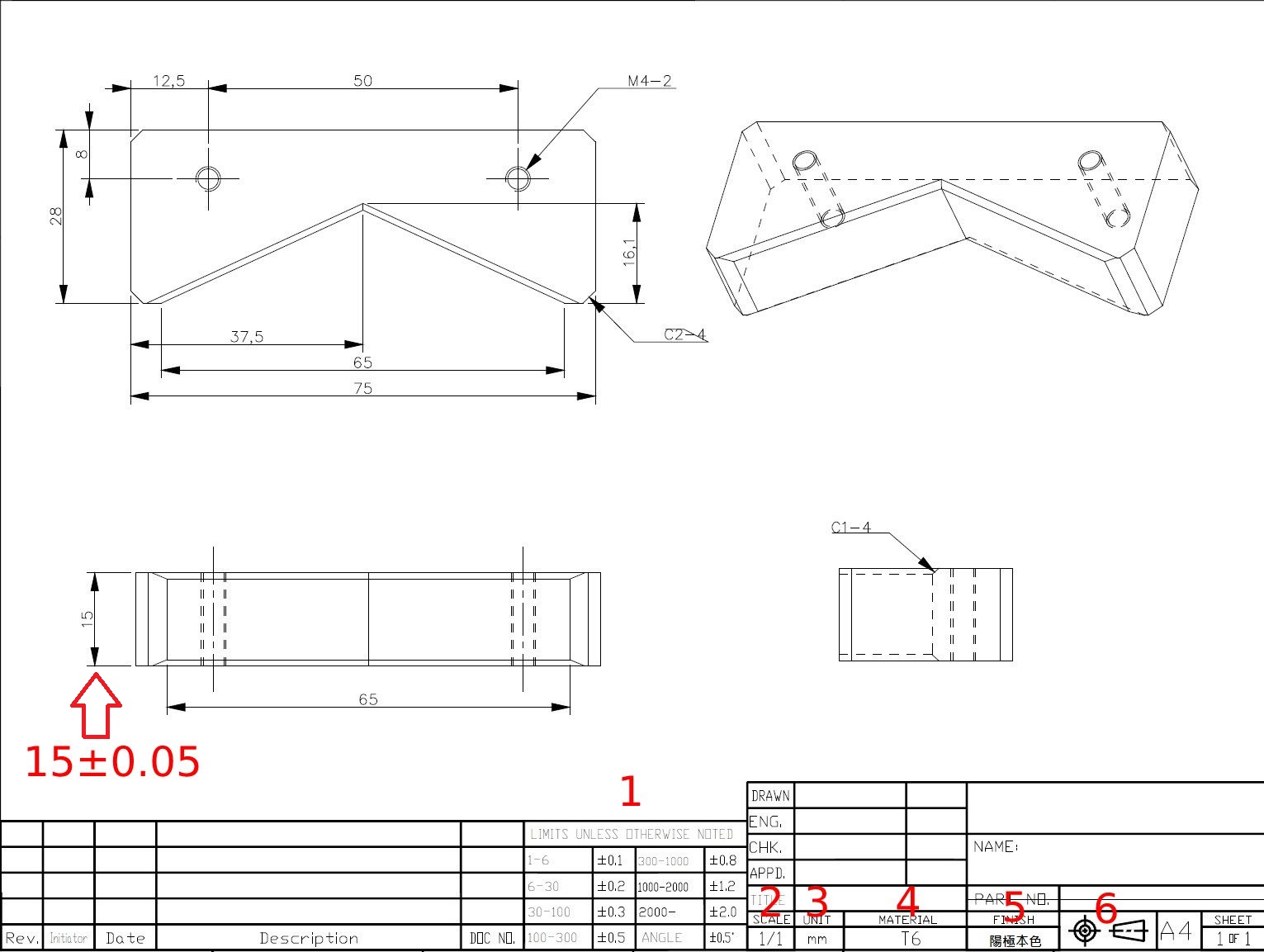

(4) Sheet Metal Working

Sheet metal working mainly involves processing thin metal sheets, usually involving cutting, bending, stamping, and welding. This method is widely used in automotive, appliance, and aerospace industries. Its advantage lies in the rapid, mass production of complex-shaped yet lightweight parts.

Case Study: We produced thin-plate fixtures for a client, successfully creating structurally sound and lightweight products using laser cutting and bending machines.

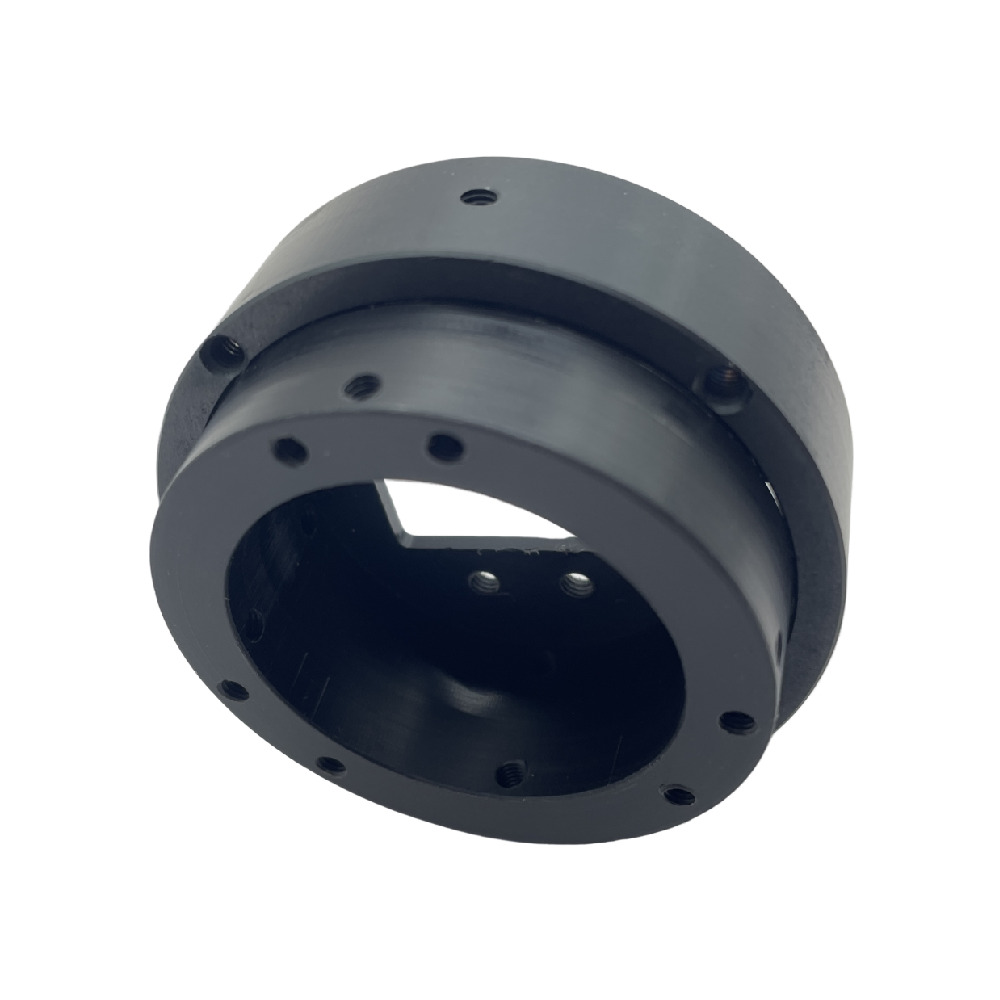

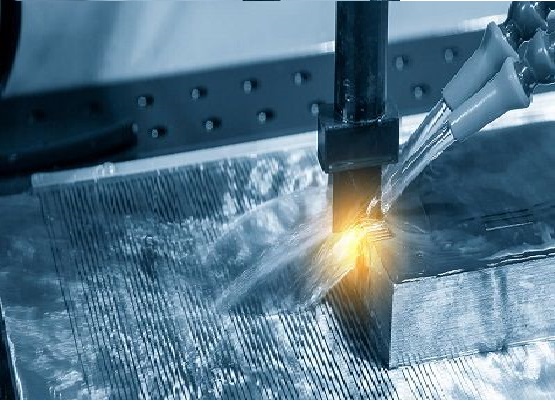

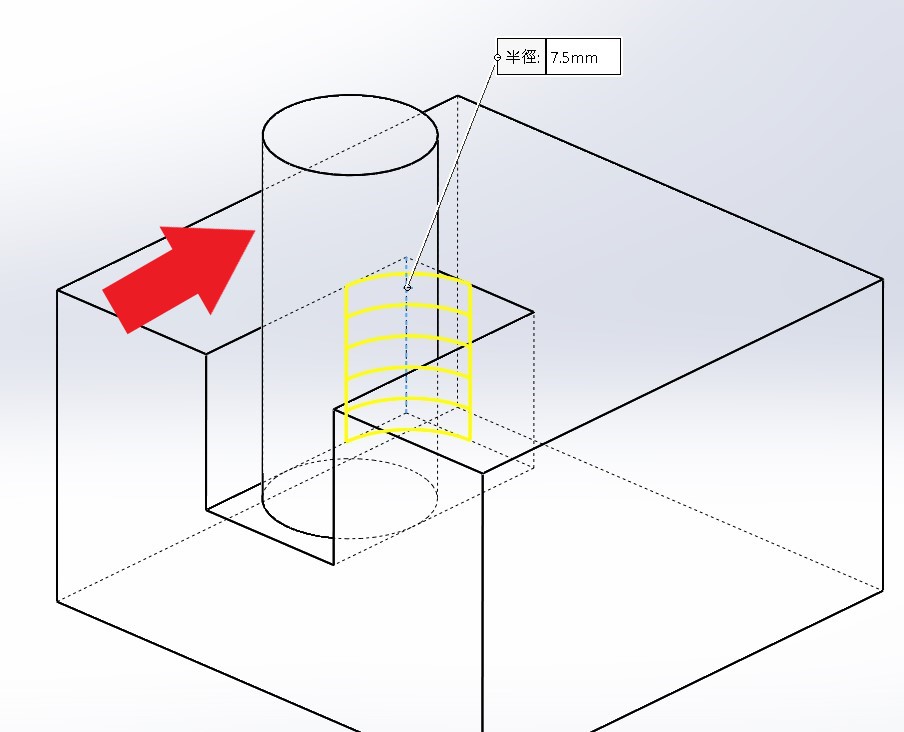

(5) Electrical Discharge Machining (EDM)

EDM is a machining method that removes material through electrical discharges from an electrode. It is primarily used for processing high-hardness materials that are difficult to machine mechanically. The EDM process uses the high temperature generated by the discharge to melt and remove metal, making it suitable for creating complex molds and high-precision parts.

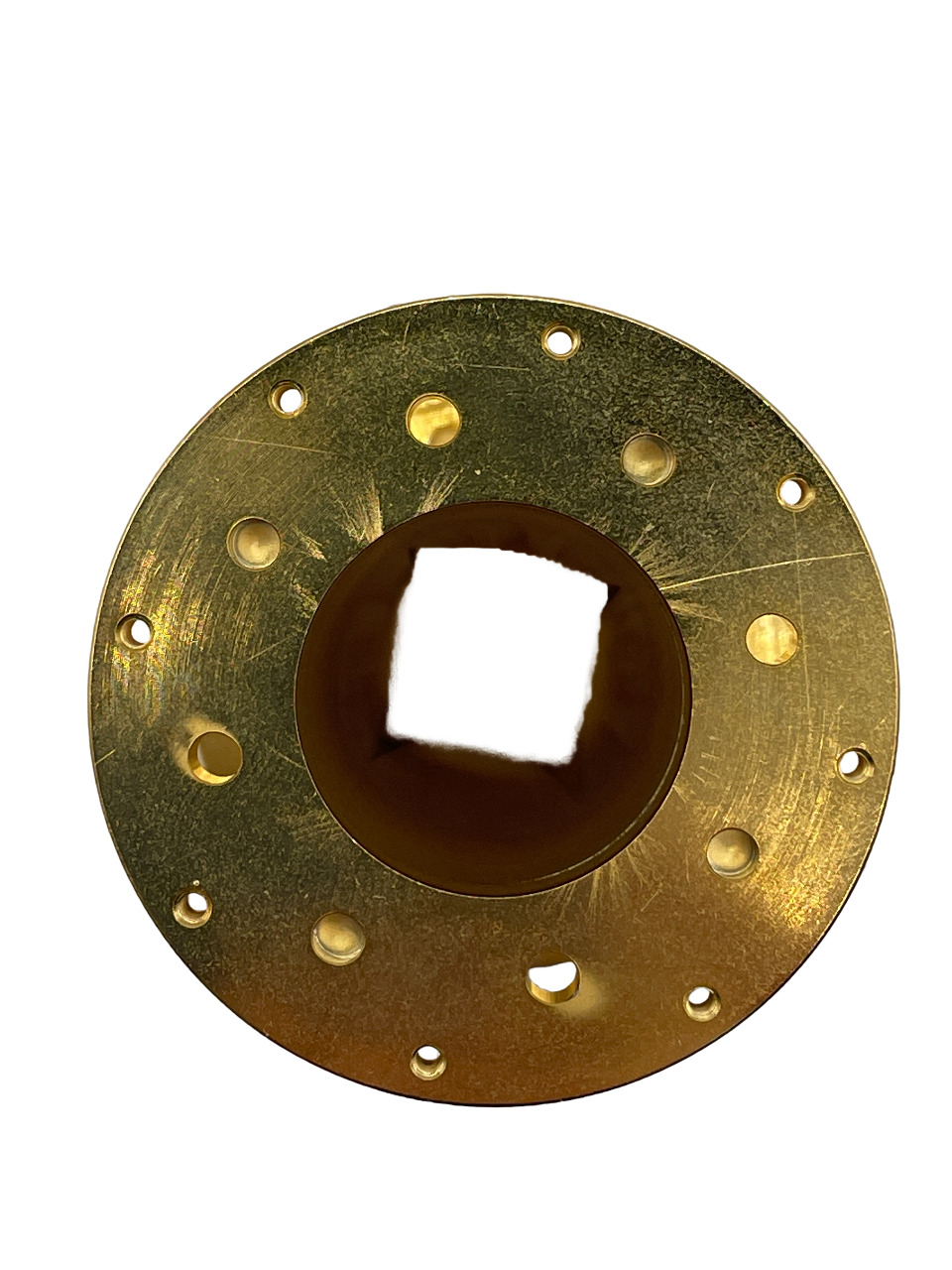

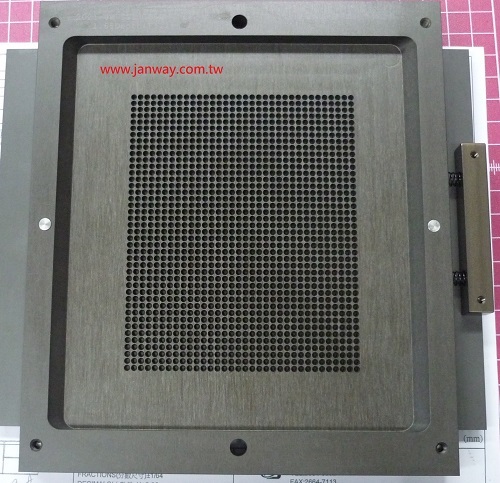

Case Study: We handled a complex part by first using CNC milling for preliminary processing, then using EDM technology to successfully create a precise square-to-round hole transition inside it.

(6) Wire Cut EDM (WEDM)

Wire Cut EDM uses a thin metal wire as an electrode to remove material via electrical spark discharge. This technology is suitable for manufacturing parts from high-hardness materials and with complex shapes.

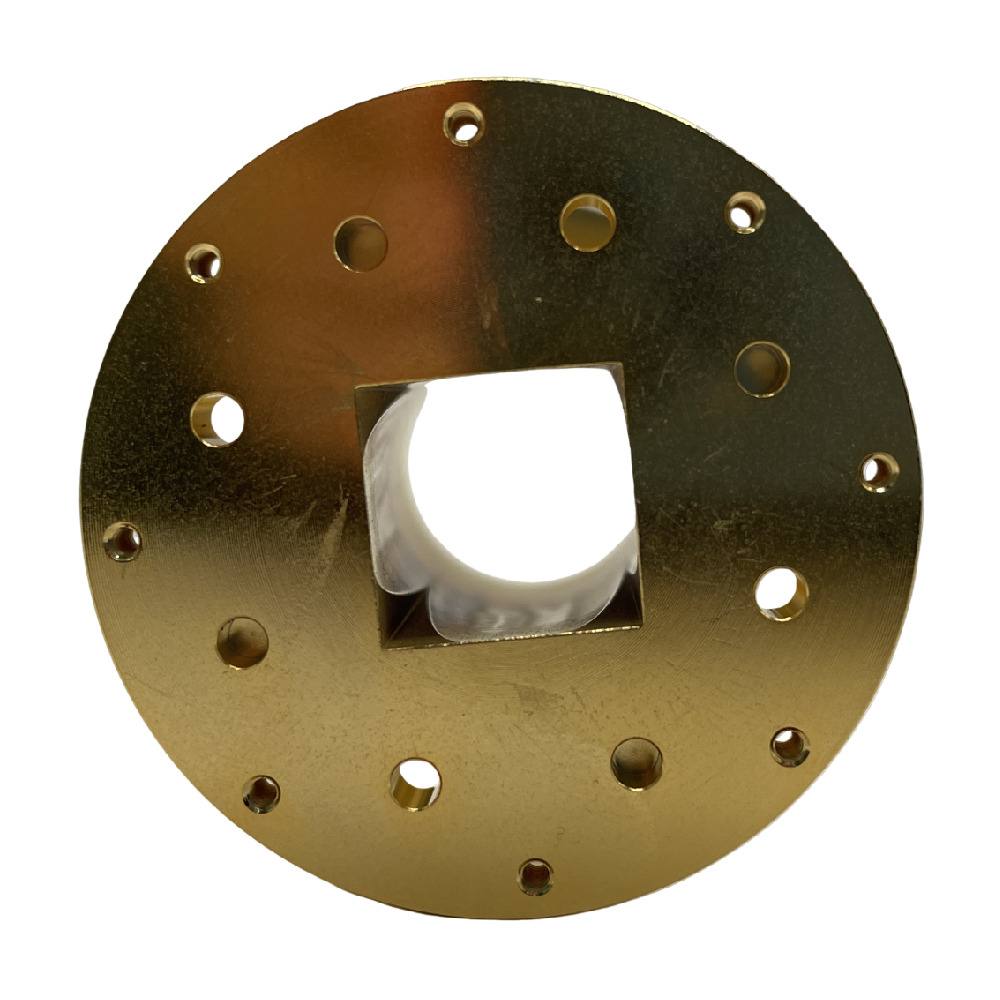

Case Study 1: Our Wire EDM technology was used to create a square hole with an extremely small corner radius (R), while the rest of the workpiece was processed using CNC milling.

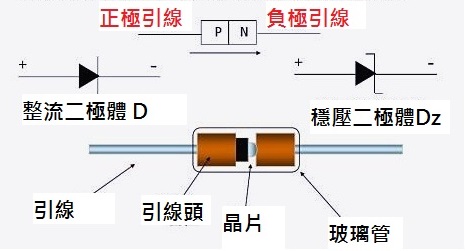

Case Study 2: This is a turned part with an elliptical slot smaller than 1mm on the head. We used Wire EDM to create this small slot because standard milling tools cannot achieve such a fine diameter, whereas the thin wire of WEDM can.

Advantages and Applications of Machining

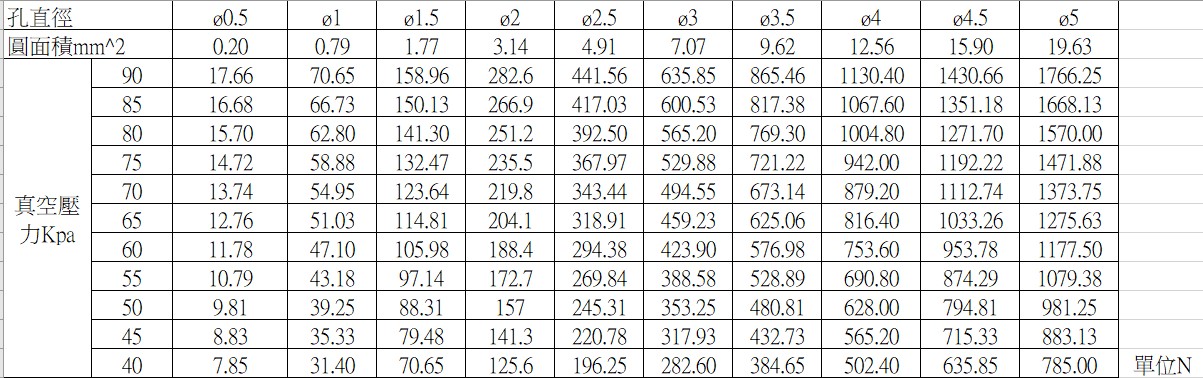

High Precision: Utilizing precise machines and tools, parts can be machined to micron-level accuracy.

Versatility: Capable of processing various metals and plastics to create complex shapes through different processes.

High Customization: Customizing machining processes according to different needs to achieve optimal cost-efficiency.

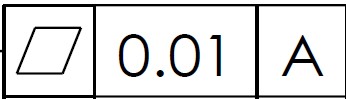

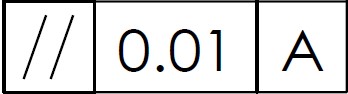

, or Parallelism

, or Parallelism  require specific processing methods. Marking tolerances is necessary, but marking tight tolerances on non-critical parts drives up costs unnecessarily.

require specific processing methods. Marking tolerances is necessary, but marking tight tolerances on non-critical parts drives up costs unnecessarily.